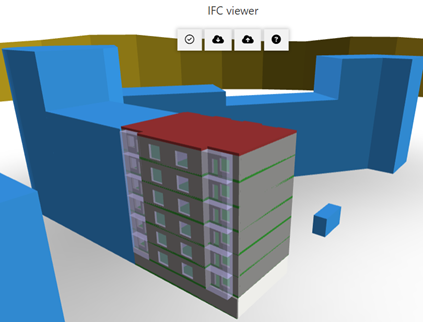

Among all the pilot buildings used to test the developments of the EPC RECAST project, 15 of them are located in Spain and conducted by our consortium partner, TECNALIA. The case presented below represents one of these Spanish pilot, located in Galdakao, a town in the north of Spain.

The pilot dwelling is sited on the 3rd floor of a 5-storey multi-family residential building. It is a relatively new building (less than 20 years old) but affected by energy regulations that are not as demanding as the current ones. Therefore, the building presents potential to improve its energy performance.

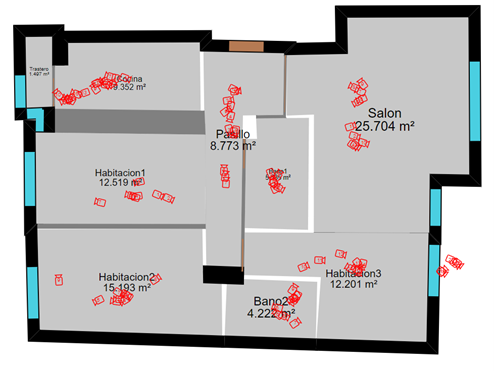

In order to check the advantages and disadvantages of the certification process developed in the frame of the EPC RECAST, an external assessor has obtained the energy performance certificate of the dwelling according to the official national certification methodology, while members of the project consortium have proceeded to obtain the certificate according to the developments of the EPC RECAST project. Therefore, first the dwelling has been scanned for the automatic generation of input data through the BIM methodology, and then calculation of the different energy indicators defined in the EPC RECAST methodology has been performed. In this way it has been possible to check the improvements offered in the certification process and the additional information offered to the user.

The most notable result in this pilot is that it has been demonstrated that the time required to obtain reliable building geometric data is reduced thanks to the EPC RECAST data acquisition methodology compared to traditional methods.

One the other hand, the reliability of the energy calculations is also being improved in this pilot thanks to the calibration process tested on it. One of the main problems that current certification schemes present is the general lack of reliability of the results. The difficulties in obtaining with certainty the real characteristics of the building, as well as the assumed calculation conditions, favor the existence of a gap between the real performance of the building and that calculated in the certification process. In order to reduce this gap, within the framework of the EPC RECAST project, a specific methodology for calibrating energy models has been developed to guarantee a more reliable energy characterization. This calibration process is being tested on Spanish pilots, including the one presented in this article.

This calibration tool developed by Tecnalia is based on an inverse modelling automatic process that aims to adjust the most influential parameters in the final energy consumption of the building, in such a way that the energy calculations offer results very close to the real consumption values of the building when exposed to the same use conditions.

Therefore, to obtain reliable information about its real behaviour and energy performance to be used by the calibration tool, the pilot has been monitored since 2022. The monitoring system implemented has made it possible to obtain information regarding the environmental conditions (temperature and humidity) both outside and inside, the energy provided by the gas boiler for heating and DHW, the total consumption of natural gas and the electricity consumption. In addition, the energy bills were also gathered.